Technical Advice - The

Worst Chimes

Worst

is sort of a harsh and judgmental term. Perhaps more accurate to

say problematic and confusing. Of the tech questions that I get,

a hugely disproportionate number of them are about these particular

models.

All time trouble-maker

prize goes to … any Rittenhouse that uses the dashpot

sequencer. These models include 360, 410 Sheffield, 520

Beverly, 610, Russel Wright and probably several others.

The natural

aluminum color of the dashpot sequencer suggests to many people

that it is a capacitor that somehow mysteriously makes the chime

work. Not so- its chock full of electromechanical gizmos. The dashpot

is a solenoid-based linear distributor in a sealed enclosure that contains

an oil bath. A solenoid quickly pushes a commutator downward, which

then is pushed upward by a spring and swipes four contacts. The

plunger's return motion is retarded by oil metered through an adjustable

port that counteracts the push of the return spring; that is what

defines the chime sequence cadence. It is an interesting and ingenious

piece of engineering, but ultimately too dependant on a delicate

balance of spring compression and torsion, friction, lubrication,

gravity, hydraulic resistance and your personal karma.

The grim truth

is that it has a finite lifespan, and the expiration date is long

past. Replacements are extinct and there is no viable service procedure.

I have attempted to repair a few with minimal success, but no longer

bother as the improvement is marginal or not successful at all.

Many of these

are still in service and still sort of working. When they fail,

they fade slowly. If yours has the typical problems of running really

slow, or not playing the last note, or getting stuck on a note leaving

the solenoid powered and buzzing, it's conceivable that you may

have luck by simply adding oil- though that has never worked for

me. Scrape off the top seal around the fill screw on the top, remove

the screw and top up the can with light oil. Beyond that simple

operation, the can must be surgically opened for additional service.

After opening it up, I experienced some improvement by shimming

the return spring to compensate for its tiredness, and cleaning

everything really well.. Then the sequencer needs to be put back

into the can and the assembly sealed with epoxy or some sort of

sealant that will be resistant to oil, and then refilled. I don’t

think the oil is anything special- just standard issue household

light oil. But like I say, the chances of this working are so slim

that I consider it to be not worth the trouble.

I have two other

ideas for how to effect a “repair”. The chime can be

rewired to bypass the sequencer and made so that it will chime just

one note. Easy enough to make it chime one note for the front door,

and different single notes for up to three other doors.

The ultimate

solution is to create a custom designed electronic sequencer to

replace the electro-mechanical dashpot. I hope that someday some

electronics expert will offer to develop that and make it available

to me and others who may need it.

Until then,

dashpot-based Rittenhouse chimes are trouble. If you have one, my

condolences. If you are thinking of buying one, like on eBay, better

to consider an alternative. While I may have a couple in my inventory

for sale, I would sell one only to someone who understands what

they are getting into.. perhaps someone for whom it has special

intrinsic value. If you have one that you are ready to give up on,

don’t send it to the landfill. I will gladly take it (or buy

for a modest amount) to scavenge parts or save for the vague future

time when I develop an electronic sequencer to solve the problem.

Most people

who find me to ask about this one say they are on a web-quest in

search of replacement parts or someone to service this one. Friends-

I have told you truth, and the whole truth. The trail ends here.

|

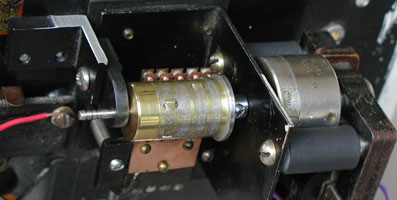

Left: dashpot in a Rittenhouse 410, typical of the later series post-war device. Enclosure is aluminum and oval in section. The pre-war version is round.

Right: inside the dashpot. |

|

Rittenhouse

with remote D-2 Timer (models 550, 525, 575)

Technically there is absolutely nothing wrong with these chimes.

They are well made, robust, easily serviced and just plain cool.

The problem is that they can be really confusing to homeowners and

especially to electricians who think they know everything there

is to know about doorbells.

The trick is

that they have a remote sequencer, aka, “D-2 Timer”.

The sequencer can be located anywhere… in an attic, crawlspace,

basement, closet, at the electrical panel.. just about anywhere,

but generally not especially close to the chime itself. Being a

4-8 note chime, the wires that are typically all inboard running

between sequencer and individual solenoids are external (i.e., in

the house walls. And there are four or five of them (common plus

one for each solenoid). In addition the sequencer has its set of

wires going to/from the door bell buttons and the power transformer.

Hence the trouble: an additional brick in the system that is totally

unique to this model, and a whole lot of extra wiring.

But there is

another more ominous problem. People have been known to confuse

the sequencer box for a transformer and apply 110v directly to it,

with predictable results.

The other issue

is that people who try to move these from one house to another—or

remove them to sell on eBay—are often unaware of the critical

need or even the existence, of the sequencer. The chime unit by

itself is interesting and can be wired to play one note for each

door bell button (as described in the dashpot topic) but it can

never play the 4-8 note sequence without a sequencer.

For those adorably naive people who think that maybe a D-2 timer

can still be had at … I don’t know... Home Depot-- NO.

This is a very specialized item that has been out of production

for 45 years made by a company that has been gone for decades. There

are none to be had anywhere.

|

Rittenhouse 550- Cool looking xylophone sort of thing, it even came with a mallet for manual striking. Largely useless without the D-2 Timer at right. The timer is what controls the 4/8note chiming sequence. The 550 is rarely found with the essential sequencer. |

|

Rittenhouse 420, 620R, 625 with Selectable Chime Sequences

Rittenhouse made two variations of the chassis used in these models. One, the simpler and lower cost model has a perfectly fine and dependable rotary distributor that controls a basic 8-note Westminster chiming sequence. The other, a fancier and more complex one, provides three user selectable sequences driven by an ingenuous but seriously trouble-prone multi-track rotary distributor. The distributor is essentially the same as the one in the more basic model, except it has multiple contact tracks and multiple feeler contacts.

The problem is that the multiple contacts create more drag on the motor - not to mention just more stuff to wear out. Add to that, the motor is no more powerful than the one on its simpler little brother, in fact it is geared to run faster, hence with less torque, and that is a contributor to the fatal flaw. Wear and friction, inadequate torque eventually conspire to cause the distributor to stall, and of course it stops at a point of highest resistance, i.e., right on a contact. Power to one of solenoids stays on until something melts or eventually burns up, or quite likely, both. Typically the fragile wire in the volume control will eventually act as a fuse and sacrifice itself for the cause. Before that actually burns out, the plastic strike pin of whichever solenoid is left powered on will probably melt. Wrapping on the affected solenoid coil also likely to burn and wither. I have seen one case where the motor also got fried.

My advice for anyone with one of these - assuming its not too late - is to decide which of the three sequences you want and then bend the contact fingers up on the other tracks so as to minimize drag on the motor. Doing that should make it just as good as the simple one-sequence variation.

If the damage has already happened… an ex-volume control can be bypassed, a melted strike pin can be reconstructed, but a fried motor may spell the end of the road. Hey- has anybody invented that electronic sequencer yet?? Could be really useful here.

|

Left: the troublesome multi-track distributor. No less than six feeler contacts drag on six tracks inviting big trouble.

Right: The simpler and generally trouble-free version has half the contacts and tracks. Vestigial markings for sequence selector seen at lower left of chassis, but not populated with the selector switch in this stripped down model. |

|

Rittenhouse

Music Box

This one is so rare that it is almost pointless to discuss, but

the topic has come up once and perhaps will show up again. The design

of this early chime is very unusual, but similar in concept to the

way a music box works. It has a motor driven cylindrical drum with

raised bumps on it. As the bumps rotate they contact and sequential

close reed switches which send current to the solenoids. It’s

an entirely wholesome concept, but the execution has a fatal flaw:

the bumps on the drum are shorter than the accumulated tolerance

and slop in the whole system, so by definition it can not work as

designed. There are other complicating factors: the motor shaft

is very long and potentially not arrow-straight. Any imperfection

in the shaft alignment is magnified by its length, plus the length

of the drum. The Telechron rotor is not necessarily rock solid in

the way it is clamped in the field coil hence it may wander off

axis. But it’s not unsolvable. The corrective action is to

add a support bearing at the end of drum, where it was originally

allowed to sway at will. Simple in theory; involved to actually

do. In my service job, all those were issues were addressed, and

the chime eventually was put back in working order, though at a

stiff cost. The one I had in for service was sent to a skilled machinist

who modified the drum and constructed the new bearing. For him,

it was not a terribly difficult job, but took 5 hours at his shop

rate. Checked into what a machinist charges lately? Makes my services

look cheap.

As mentioned,

this one is the only one of this model I have ever seen. My sense

is that the model had an extremely short life span as it’s

hard to imagine that it ever worked. In fact I suspect that of those

number that were sold, many were returned and destroyed... and the

rest were probably just tossed.

|

The Rittenhouse "Music Box" sequencer mechanism after modifications. The left end of the rotary drum was extended to add a bearing axel; an adjustable bracket to support the axel also added. Bolsters were added to the motor field coil standoffs to help stabilize the Telechron rotor. Bank of five reed switches visible behind the drum. |

Are you seeing

a pattern here? Like maybe all the trouble makers are by one manufacturer?

While true, my sense is the reason for that is that Rittenhouse

engineers were working overtime to come up with creative solutions

with the likely goal of avoiding existing intellectual property,

in particular the 1930 Rodet patent for a multi-note chime sequencer.

While Rittenhouse made some forays over the flakey edge, most of

their products were of more traditional design and top notch quality.

|