Some of the most deluxe chimes included a clock. A few extremely rare models have a time chime function in addition to the doorbell function, but for the vast majority the clock was just an add-on feature to make the housing more than a simple cover. The clocks are powered by the same stepped-down voltage provided by the system transformer for the door bell function.The most commonly used clock movement was the venerable Warren or GE Telechron. What I’ve read is that Telechron closed shop many years ago, but just before closing, made tons of replacement rotors to keep Telechron clocks running for a very long time. The effect of this is that there is a significant, but definitely finite number of replacement rotors out there to be had. The result is that what was once a couple dollar item can now cost $50- $200. There are a few specialists who rebuild these, so the long term prognosis is good, though potentially pricey. For those willing to work at it a bit, a used rotor can be scavenged from one of the zillion clocks and other devices that used a Telechron motor and can potentially be bought dirt cheap.

Considerably harder to find may be a clock repair shop that wants to help. I heard of one person trying to get her 24v Telechron repaired and was told by one repair shop that it was hopeless because the rotor was discontinued. Well, duh! As far as I have been able to determine, the rotors are largely interchangeable, specifically that any part number across a letter series is interchangeable within that letter series. For instance if you have a clock with an H3 M3151 rotor, it can be replaced with any other H3 M-series rotor. I have replaced a few rotors with new rotors of non-matching numbers with excellent result and clock experts that I have consulted confirm the interchangeability. The part that is unique to a low voltage version is the field coil.

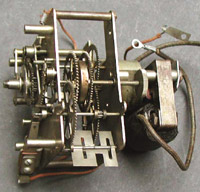

The other very common condition that I have found with 50 year old Telechrons is that the gear works lock up. This is quite evident by the symptom of the setter stem being stuck so it will not turn to manually set the time. Professionals probably have a more gentle approach, but what I have done is to disassemble the clock to the point that I can extract the gearworks module, and then give it an aggressive cleaning with degreaser. Works for me.

One problem frequently found on Jeffersons is that the power cord has been yanked on and has ripped loose the leads into the field coil. It is an amusingly thoughtless design that lacks any sort of strain relief in a situation where yanking on the cord is a guaranteed eventuality. Easily remedied though; when replacing the petrified cord – which is usually necessary – just make it long enough to tie it to the field coil to create an effective strain relief.

When Telechrons fail I prefer the repair route, keeping everything original. Telechron movements are a significant part of time keeping history and an engineering and even cultural milestone-- and that is part of the argument for repair. In my view, it is also much easier to repair a Telechron clock motor than it is to do a quartz conversion, and that is the compelling reason to keep the original Telechron clock intact.

While I recommend Telechron repair, I find it laughable when people are aghast at the idea of quartz conversion. If the primary concern for you is the utility of having an accurate and dependable clock, a battery operated quartz movement conversion may be the better choice. They are accurate, very low cost, readily replaceable, and don’t stop during a power outage. Yes, they are “cheap”...just like a Telechron movement was a "cheap" clock in 1935. Look- a NuTone Jefferson was designed to be a fake antique from day one no matter how you slice it, and a Telechron clock was the polar opposite of a fine handmade movement. They are nice like Disneyland is nice, but confusing one with a fine handcrafted antique deserving of only exquisite originality is just to lack an understanding of what it is and what it is not.

Things get a

lot sticker when it comes to brands other than Telechron. Synchron

brand motors were also used widely, and Haydon and Ingraham less

commonly. By my experience, parts for these brands are non-existent

and even finding salvageable movements in the used market is almost

impossible. And most clock shops, generally reluctant to touch any sort

of electric clock - let alone low voltage variants - won’t even talk about these less common

brands. In such cases, quartz conversion may be the only viable solution

for repair.

Here are a few

considerations if doing a quartz conversion. Fitting the old hands

is a simple if tedious task that just requires patience and a set

of jeweler’s files. I’ve been using continuous motion

movements so the hands have the smooth motion of the vintage movements.

When converting to new quartz movement there may be a tradeoff to

deal with: the new clocks typically have longer shafts, and the stack

of hour, minute and second hands might not fit under the original

glass (if the clock has glass). Eliminating the second hand, not

using the glass, or using a higher domed glass might be the choices.

The caveat to all this is that I am decidedly not a clock expert. I have found one helpful clock repairman who has advised me on clock matters and is willing to do service on low voltage electric clocks. If you are looking for clock repair, contact him from my links page, and let me know how it goes.

|

The wildly popular Nutone Jefferson K46 with a 16v or 24v Telechron.

|

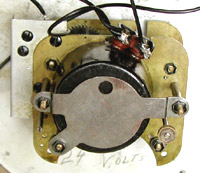

Telechron field coil.

|

Telechron rotor. Earlier better quality models have a copper housing.

|

| |

Power leads tied to Telechron field coil frame creates a sorely needed strain relief.

|

Edwards 1490 time chimer powered by a Telechron motor.

|

| |

Ingraham time chimer from a Rittenhouse 620.

|

Haydon spot welded to a clockworks grearbox from a Nutone L35.

|

| |

|